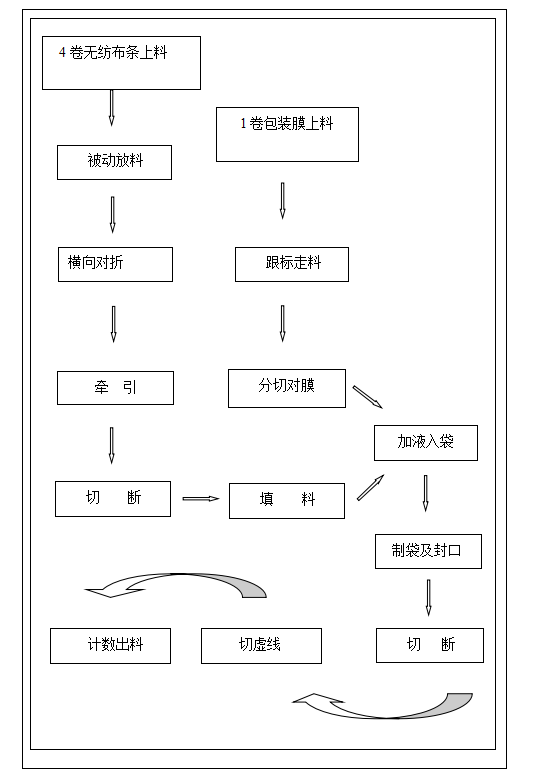

一、工程流程

二. 说明

1. 被动放卷:无纺布在主机牵引轴拉动下被动放卷,避免无纺布与PVC皮带发生摩擦防止材料污染。

2. 横向对折:304不锈钢折叠机构,无纺布通过过程中保证制品清洁,折叠位置的精准。

3. 牵引:伺服电机传动定长牵引,长度误差控制在正负0.1cm,无纺布受力均匀,材料无过度拉伸。

4. 切断:采用上飞刀下定刀剪切式切断,无纺布切口整齐无棉絮及连丝。

品质控制方法:每天工作前检查刀口锋利程度,及时打磨换新。

5. 填料:折叠切断后的无纺布通过传动辊位移至下层包装膜填料位置,通过下膜托送至加液位置

6. 加液入袋:PLC控制可调液量的灌液系统定时加液,加液泵采用高精度电子隔膜泵,有效防止液体内杂质进入产品。加液后立即覆盖上层包装膜。

品质控制方法: 机械部分调整加液管高度防止液体喷溅出棉片位置。触摸屏内可调整加液时间改变加液量。

7. 包装膜上料:上料位置可调,包装膜放卷横向手动纠偏系统,控制因纸芯位置偏差造成的产品边缘露白的情况。

8. 跟标走料:松下全色彩识别型光电传感器,严格按照印刷排版版面控制袋长。

9. 分切对膜:不锈钢刀片居中分切包装膜成上下两层,两层材料分别通过多根过料轴完成正反面对版。

10. 制袋及封口:双温控调温模具进行两次纵封和一次横封,封口模具压力及温度可调。

品质控制方法: 每组上下模具封口花纹互为阴阳,加温的同时通过阴阳面咬合牢牢密封住酒精棉片,温度和压力可以通过温控仪和压力表数显,以便精准控制封口温度和压力,达到封口效果的品质把控。

11. 切断:采用上飞刀下定刀剪切式切断,包装袋切口整齐无毛边,出料整齐。

12. 切虚线:每片酒精棉片成品的包装膜两两之间以虚线刀分切,方便批量取料和单片取用。

13. 计数出料:计切刀工作次数配合跑步电机出料,正常低速出料,到数后疾走将前后两组材料拉开距离方便收料。